Our Services

- Home

- Our Services

What Do We Offer

Tool Manufacturing

At our company, we specialize in tool manufacturing, catering to a wide range of industries and applications. Our skilled team is experienced in designing and manufacturing various types of tools, including dies, molds, jigs, and fixtures. By manufacturing our own tools in-house, we have better control over the quality and timelines of the production process. This allows us to optimize manufacturing efficiency, reduce costs, and ensure that our clients receive high-quality tools tailored to their unique manufacturing needs.

Product Designing

Our product design process involves a systematic approach that encompasses various stages, from concept development to commercialization. We collaborate closely with our clients, working hand in hand to understand their requirements, target market, and desired outcomes. By involving our team from the initial stages of idea generation, we can leverage their expertise and creativity to develop unique and impactful designs.

Simulations

Simulation is a valuable tool we utilize to optimize designs and improve performance across various industries. By leveraging simulation software, we can create virtual models and conduct virtual experiments to assess the behaviour and performance of our designs under different conditions. Simulation allows us to accurately analyse and predict the performance of complex systems, such as fluid dynamics, structural integrity, thermal behaviour, and more.

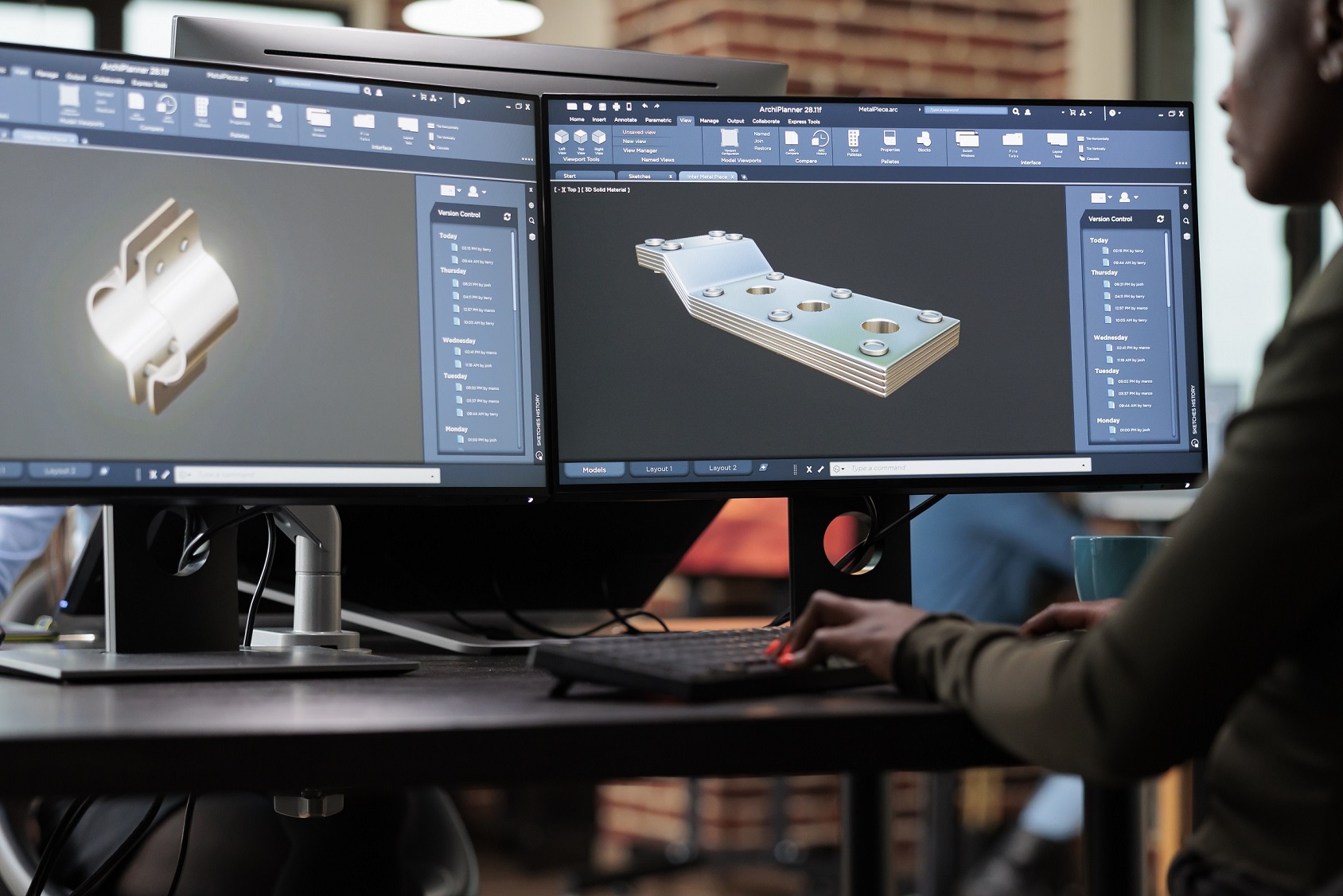

CAD System

CAD (Computer-Aided Design) systems play a crucial role in supporting our research and development activities at our company. By utilizing CAD systems, we can create, modify, analyze, and optimize designs with greater ease and efficiency. These systems provide powerful tools and functionalities that enhance the entire design process, from conceptualization to finalization. As a result, we can effectively meet the evolving needs of our customers and maintain a competitive edge in the industry.

Automation Engineering

Our automation engineering services include the utilization of advanced pick and place machines to streamline component work in our company. This technology significantly minimizes the need for manual intervention, allowing us to optimize productivity and free up valuable human resources for more complex tasks. They ensure seamless integration of the machine into our production line and collaborate closely with the machine's manufacturer to leverage its full potential.